Peripheral drive bridge type scraper for neutralization and sedimentation tank

Working Principle

The sewage enters from the inlet pipe at the center of the tank, spreads out through the guide cylinder and flows radially towards the periphery. The sludge settles at the bottom of the tank, and the supernatant is discharged from the effluent trough through the overflow weir plate. Driven by the peripheral drive device, the main girder travels along the top of the tank with the central rotating support as the axis. The sludge scraping plates connected below the main girder scrape the sludge at the bottom of the tank from the periphery of the tank to the central sludge collecting trough, and it is discharged out of the tank through the sludge discharge pipe relying on the water pressure in the tank. At the same time, the scum scraping plate skims the scum floating on the liquid surface towards the periphery of the tank for collection and discharge.

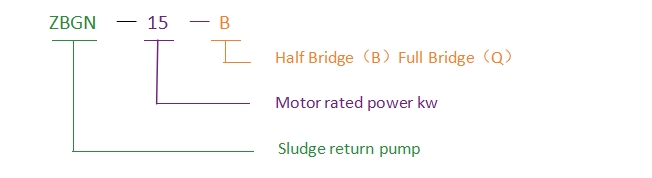

Model Denotation

parameters and selection

|

Model |

ZBGN-16 |

ZBGN-20 |

ZBGN-25 |

ZBGN-30 |

ZBGN-35 |

ZBGN-40 |

ZBGN-45 |

ZBGN-50 |

|

|

Pool diameter D(m) |

16 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

|

|

Pool Depth H(m) |

1~4.5 |

||||||||

|

Scraper outer edge speed(m/min) |

primary sinking pond |

3 |

|||||||

|

|

Second sinking tank |

1.8 |

|||||||

|

Unilateral driving power(kw) |

primary sinking pond |

1.1 |

1.5 |

2.2 |

|||||

|

|

Second sinking tank |

0.37 |

0.55 |

0.75 |

1.1 |

||||

|

D1(mm) |

3000 |

3000 |

3400 |

4000 |

4500 |

5000 |

5500 |

5800 |

|

|

D2(mm) |

2500 |

2500 |

2900 |

3400 |

3850 |

4300 |

4800 |

5000 |

|

|

B(mm) |

300 |

300 |

300 |

300 |

400 |

400 |

450 |

450 |

|

|

B1(mm) |

500 |

500 |

500 |

500 |

550 |

600 |

600 |

650 |

|

|

H1(mm) |

800 |

800 |

900 |

1100 |

1200 |

1300 |

1400 |

1500 |

|

|

H2(mm) |

450 |

450 |

500 |

500 |

500 |

500 |

500 |

500 |

|

|

H(mm) |

3600 |

3600 |

3600 |

4000 |

4000 |

4400 |

4400 |

4600 |

|

|

|

4000 |

4000 |

4000 |

4400 |

4400 |

4800 |

4800 |

5000 |

|

|

n(general classifier) |

113 |

123 |

148 |

188 |

218 |

248 |

268 |

288 |

|

Structural composition

1. Drive Mechanism: Generally, it is directly connected and driven by a drive reducer and a driving roller. For example, when using a shaft-mounted gear reduction motor, the structure is compact, and it can drive the working bridge to rotate along the periphery of the sedimentation tank.

2. Main Girder: Usually made of square steel, it has high strength. After hot-dip galvanizing and topcoat spraying processes, it has strong anti-corrosion performance and can bear the load of the sludge scraping system and others.

3. Central Rotating Support: Composed of a rotating turntable, fixed seat, slewing bearing, central collector ring, carbon brushes, etc., it mainly bears the axial load and part of the radial load of the equipment.

4. Sludge Scraping System: Includes sludge collecting scrapers and connecting brackets, made of stainless steel plates and profiles, which scrape the sludge at the bottom of the tank to the sludge tank at the bottom of the tank.

5. Skimming Device: Such as skimming plates and articulated skimming rakes, mostly made of stainless steel plates, which can scrape the scum floating on the liquid surface in the tank from the center of the tank to the skimming hopper for discharge.

Characteristics

It is widely used in sewage treatment projects of urban water plants, urban sewage treatment plants, chemical, textile, metallurgical and other industries. It is mainly used for sludge discharge in circular sedimentation tanks, generally for occasions with a large tank diameter, and is especially suitable for scraping and discharging the sludge at the bottom of the secondary sedimentation tank.

Application

It is suitable for aquaculture, such as the aquaculture ponds for fish, shrimps, crabs, eels, etc. It can also be used for aerating urban river water bodies, improving and maintaining the water quality of lakes and ponds. It can drive the water cycle and supply the oxygen required for the growth of plants and animals at the bottom of ecological rivers and lakes, and improve and reduce the bottom sediment.