A water company in Guizhou purchased a WLS shaftless screw conveyor from Nanjing Lanjiang

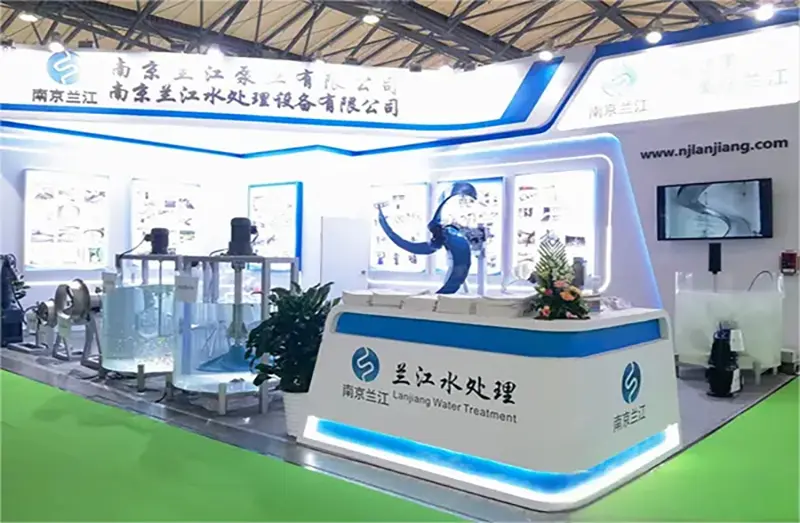

Nanjing Lanjiang Pump Industry Co., Ltd. (affiliated to Nanjing Lanjiang Water Treatment Group) is a leading domestic sewage treatment equipment manufacturer. With its technical strength and industry reputation, it has become the preferred partner for a water company in Guizhou to purchase a WLS Shaftless Screw Conveyor. This equipment is designed for complex material transportation and has excellent performance in environmental protection, chemical, food and other industries. The following is an introduction from three aspects: product performance, application scenarios and corporate services.

Product performance advantages

1.Shaftless design, strong anti-clogging

The WLS shaftless screw conveyor adopts a center shaftless structure and pushes materials through flexible steel spiral blades, which completely solves the problem of easy winding and easy clogging of traditional shafted equipment. It is especially suitable for conveying sticky sludge, domestic garbage, waste paper pulp and other easy-to-wind materials. Its torque is as high as 4000N·m, which can be smoothly transported at low speed, and the energy consumption is reduced by more than 30% compared with traditional equipment.

2.Efficient transportation, flexible customization

The equipment's transportation capacity is 1.5 times that of a shaft screw machine with the same diameter, up to 458m³/h (depending on the model), with a single machine length of 60 meters, and supports multi-stage series installation to achieve ultra-long distance transportation. In addition, users can customize the inlet and outlet positions, inclination angles (<20°) and lining materials (such as wear-resistant plastic, rubber or cast stone) according to their needs to adapt to high temperature and corrosive environments.

3.Both environmental protection and durability

The fully enclosed structure is matched with an easy-to-clean surface to prevent material leakage and contamination, meeting the hygiene requirements of the food and pharmaceutical industries. The trough body is made of seamless steel pipes and wear-resistant linings, with a long service life and low maintenance costs. It is equipped with a mobile model and can be flexibly deployed in different operating scenarios.

Core application areas

WLS equipment is widely used in:

1.Environmental protection projects: conveying screen residue and mud cake in sewage treatment plants, and urban solid waste treatment;

2.Chemical and papermaking: closed transmission of viscous chemical raw materials and waste paper pulp;

3.Food processing: clean transportation of hygienic sensitive materials such as malt and fruit and vegetable waste.

Nanjing Lanjiang's corporate guarantee

Nanjing Lanjiang has more than 20 years of industry experience, passed ISO9001 certification and many provincial quality honors, and its technical team can provide one-stop service from design to after-sales. Its production base is located in Nanjing Liuhe Development Zone, equipped with modern plant and testing equipment to ensure that the product is strictly debugged before leaving the factory and supports customized needs (such as explosion-proof, high temperature resistant and other special working conditions design).

Summary

A water company in Guizhou chose Nanjing Lanjiang's WLS shaftless screw conveyor not only because of its excellent conveying performance and environmental protection design, but also because of the company's reliable technical support and after-sales service. This equipment will effectively improve material handling efficiency, reduce operation and maintenance costs, and provide solid protection for enterprises in terms of environmental compliance and production optimization.