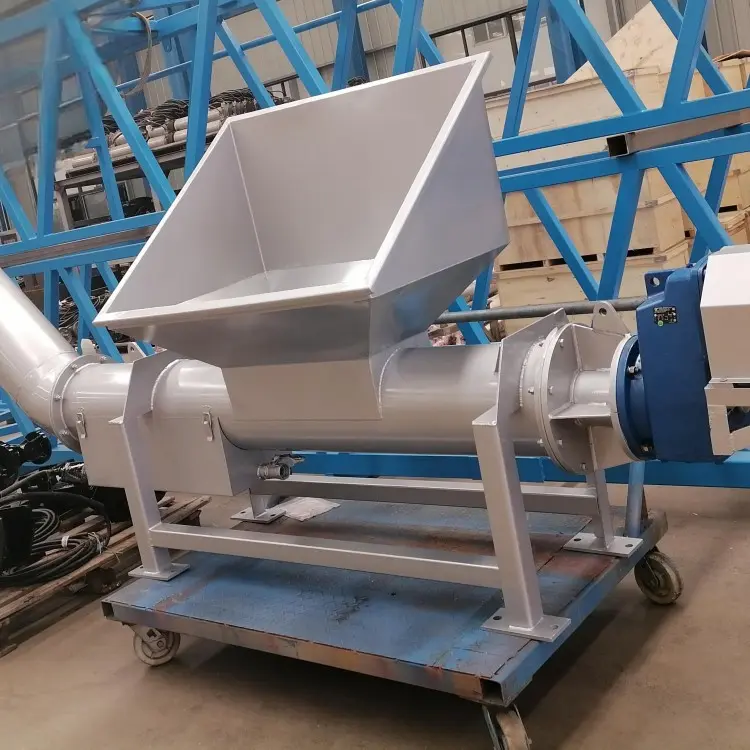

High Drainage Screw Press Sludge Dehydration Equipment

Key Features

1. Efficient Separation: Achieves high-efficiency solid-liquid separation through continuous squeezing by the spiral shaft.

2. Compact Structure: The equipment occupies a small footprint, making it suitable for spaces with limited area.

3. High Automation: Can be equipped with an automatic control system, making operation simple and reducing manual intervention.

4. Strong Adaptability: Suitable for various materials, such as fruits and vegetables, kitchen waste, sludge, etc.

5. Energy-Efficient and Eco-Friendly: The separated liquid can be recycled, and the solid can be further processed, reducing resource waste.

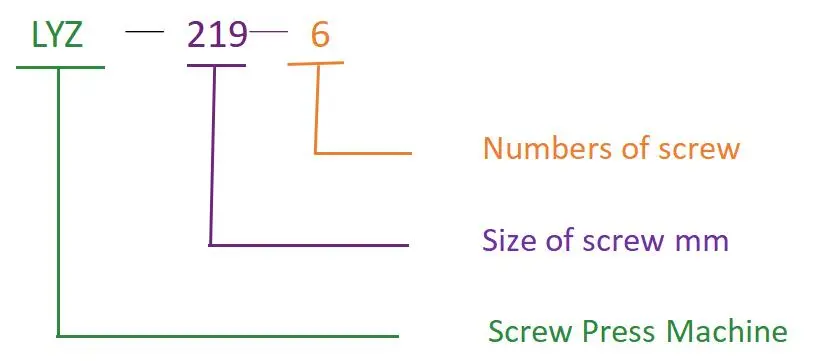

Model of Model Denotation

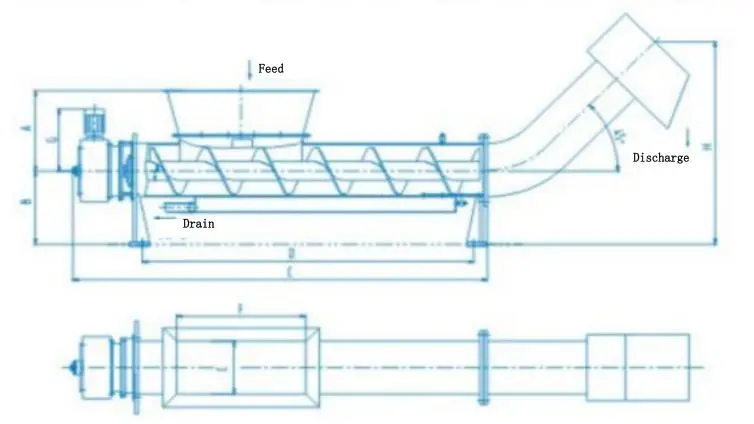

Host overall size

Main technical parameters,size table

Model |

Number of spiral turns |

Spiral tube size |

A |

B |

C |

D |

E |

F |

G |

H |

Motor power |

LYZ219/6 |

6 |

219 |

400 |

380 |

1500 |

1030 |

400 |

540 |

422 |

1000 |

1.1 |

LYZ219/9 |

9 |

219 |

400 |

2100 |

1570 |

400 |

1080 |

422 |

1000 |

1.1 |

|

LYZ219/11 |

11 |

219 |

400 |

2500 |

1930 |

400 |

1440 |

422 |

1000 |

1.1 |

|

LYZ299/6 |

6 |

299 |

500 |

2150 |

1380 |

450 |

750 |

501 |

1200 |

3 |

|

LYZ299/9 |

9 |

299 |

500 |

3050 |

2240 |

450 |

1500 |

501 |

1200 |

3 |

|

LYZ299/11 |

11 |

299 |

500 |

3650 |

2740 |

450 |

2250 |

501 |

1200 |

3 |

|

LYZ402/6 |

6 |

402 |

600 |

2700 |

1940 |

750 |

900 |

622 |

1350 |

5.5 |

|

LYZ402/9 |

9 |

402 |

600 |

3900 |

2930 |

750 |

1980 |

622 |

1350 |

5.5 |

|

LYZ402/11 |

11 |

402 |

600 |

4700 |

3590 |

750 |

2640 |

622 |

1350 |

5.5 |

Working Principle

The spiral press uses the rotation of the spiral shaft to push materials from the inlet to the outlet. During the process, the materials are squeezed by the spiral blades and the screen, allowing the liquid to pass through the screen while the solid is discharged from the outlet.

1. Feeding: Materials enter the press through the inlet.

2. Squeezing: The spiral shaft rotates, pushing the materials forward and gradually squeezing them.

3. Separation: The liquid passes through the screen, while the solid continues to move forward.

4. Discharge: The solid is discharged from the outlet, completing the separation process.

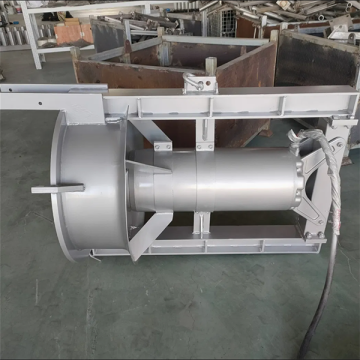

Main Components

1. Spiral Shaft: The core component that pushes and squeezes materials through rotation.

2. Screen: Used to separate liquid and solid, with screen aperture selectable based on material characteristics.

3. Inlet: The entry point for materials into the equipment.

4. Outlet: The discharge point for separated solids.

5. Liquid Collection Trough: Collects the liquid discharged through the screen.

6. Drive Unit: Includes a motor and gear reducer to drive the rotation of the spiral shaft.

Applications

1. Food Processing: Used for fruit and vegetable juicing, bean residue dewatering, etc.

2. Environmental Industry: Used for kitchen waste treatment, sludge dewatering, etc.

3. Agriculture: Used for dewatering straw, feed, etc.

4. Chemical Industry: Used for solid-liquid separation of chemical raw materials.

5. Biomass Energy: Used for pretreatment of biomass fuel.

Selection and Installation

1. Selection Basis:

- Material properties (moisture content, viscosity, particle size, etc.).

- Processing capacity requirements.

- Separation efficiency requirements (solid content in liquid, moisture content in solid, etc.).

2. Installation Points:

- Ensure the equipment is installed horizontally to avoid vibration and noise.

- The inlet and outlet should be smoothly connected to upstream and downstream equipment.

- The power supply and control system must meet the equipment requirements.

Maintenance and Care

1. Regular Inspection: Check the wear and tear of the spiral shaft, screen, and other components, and replace worn parts promptly.

2. Cleaning and Maintenance: Regularly clean residual materials inside the equipment to prevent clogging and corrosion.

3. Lubrication: Regularly lubricate bearings and transmission components to ensure smooth operation.

4. Replacement of Wear Parts: Replace screens, seals, and other wear parts in a timely manner to maintain separation efficiency.

With its high efficiency, energy-saving features, and strong adaptability, the spiral press plays an important role in various industries and is an ideal equipment for solid-liquid separation.