In various industries, the role of an Industrial Tank Agitator is crucial. These devices facilitate optimal mixing solutions for different applications. Effective mixing can significantly influence product quality and production efficiency.

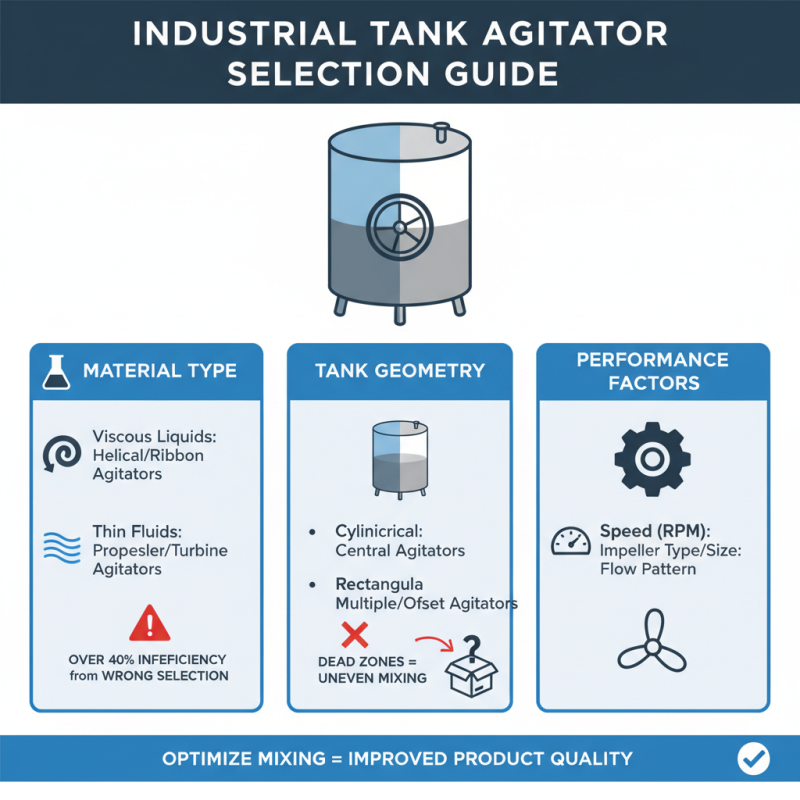

Selecting the right Industrial Tank Agitator is not a simple task. The market offers numerous options, each with unique features. Not all agitators meet specific operational needs. It is essential to assess the required speed, viscosity, and tank geometry.

Choosing poorly may lead to unsatisfactory results. Some may struggle with intangible factors, such as energy efficiency. Evaluating these agitators should involve careful consideration of various parameters. Only by reflecting on these factors can companies achieve the desired mixing outcomes.

When selecting industrial tank agitators, several key considerations come into play. The type of material being mixed is fundamental. For example, viscous liquids require different agitator designs compared to thin fluids. Reports indicate that over 40% of mixing inefficiencies are due to improper agitator selection. Tank geometry also affects performance. A poorly matched agitator can lead to dead zones. These areas cause uneven mixing, which can compromise product quality.

Another critical factor is the power and energy consumption of the agitator. Energy-efficient models can reduce operational costs by up to 30%. However, some designs may not provide adequate mixing for specific applications. The right balance between efficiency and performance is essential. It's important to assess the required mixing intensity and the desired end product quality. Various factors, including tank size and the number of phases in the mixture, also play a role.

Lastly, analyzing your maintenance needs is vital. Some agitators may require extensive upkeep, which could interrupt production. Reports show that poorly maintained agitators contribute to a 20% increase in downtime. It's crucial to consider these points to improve mixing outcomes efficiently. Often, overlooking simple details can lead to larger issues down the line. Prioritizing these considerations can create a more reliable mixing process.

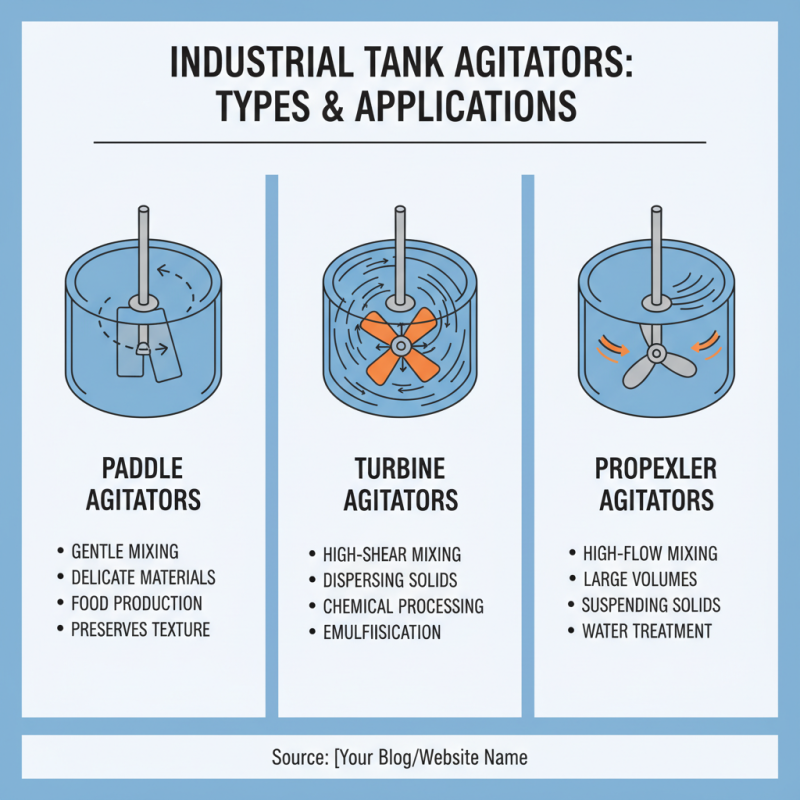

When it comes to industrial tank agitators, understanding the various types and their applications is key. Different processes require different mixing techniques. For instance, paddle agitators are commonly used for gentle mixing of delicate materials. This makes them ideal for food production where preserving texture is crucial.

On the other hand, turbine agitators provide a more vigorous mixing action. They are often used in industries where blending components is essential, such as in chemical manufacturing. The shape and speed of the turbine can greatly affect the mixing efficiency.

**Tip:** Always assess the viscosity of your materials. Choosing the wrong agitator can lead to poor mixing outcomes.

Another important type is the magnetic stirrer. It's perfect for small-scale operations, particularly in laboratories. This type ensures a consistent mixture without physical contact, reducing contamination risks.

**Tip:** Regular maintenance of agitators can prevent unexpected breakdowns. Even minor wear can affect performance significantly.

In summary, evaluating the specific needs of your process will help in selecting the right agitator. The implications of the wrong choice can be costly and challenging.

When considering tank agitators, several key features ensure effective mixing. A balance of power and speed affects fluid dynamics. Proper agitation requires a thorough understanding of the viscosity of the materials being mixed. High-viscosity liquids often need more powerful agitators. Studies have shown that a well-optimized agitator can reduce energy consumption by 15-30%.

Material choice for the agitator blades is crucial too. Stainless steel is commonly favored due to its strength and resistance to corrosion. However, specific applications may benefit from composite materials. It's vital to consider the operating environment before making a choice. A poorly chosen material can lead to frequent maintenance issues.

**Tips:** Pay attention to your tank size. The impeller design should match the tank's volume. Optimal placement enhances shear and flow rates. Also, consider the mixing time. Adjusting the speed can significantly alter the mixing outcome. Always evaluate and test different configurations for the best results. Often, time is as critical as power in achieving the desired homogeneity.

| Model | Motor Power (kW) | Tank Capacity (Liters) | Agitation Type | Control Type |

|---|---|---|---|---|

| Model A | 5 | 1000 | Mechanical | Manual |

| Model B | 7.5 | 1500 | Hydraulic | Automatic |

| Model C | 3 | 500 | Magnetic | Manual |

| Model D | 10 | 2000 | Mechanical | Automatic |

| Model E | 2 | 300 | Magnetic | Manual |

| Model F | 6 | 1200 | Hydraulic | Automatic |

| Model G | 8 | 1800 | Mechanical | Manual |

| Model H | 4 | 600 | Magnetic | Automatic |

| Model I | 1.5 | 200 | Hydraulic | Manual |

| Model J | 9 | 1600 | Mechanical | Automatic |

Maintaining industrial tank agitators is crucial for optimal performance. Regular maintenance can extend the lifespan of these machines significantly. According to industry reports, timely maintenance can reduce breakdown rates by up to 30%. This not only saves costs but ensures continuous production.

Inspect seals and bearings regularly. Wear and tear on these components can lead to leaks and inefficiency. Addressing issues early can prevent larger problems down the road. Lubrication is essential too. Proper lubrication decreases friction and heat, reducing wear.

Monitoring vibration levels is also critical. Excessive vibrations can indicate misalignments or imbalances. Early detection can prevent catastrophic failures. It's essential to have a measurement system in place. Analyzing data over time can provide insights into performance trends. However, many facilities overlook these steps, leading to unexpected downtimes.

This bar chart illustrates the effectiveness of various types of industrial tank agitators based on their energy consumption and mixing efficiency. An optimal agitator not only reduces operational costs but also enhances productivity in industrial settings.

Agitators play a critical role in various industries, especially in chemical processing and food production. Their efficiency directly impacts product quality. Recent industry reports indicate that the global market for industrial agitators is projected to reach $4.5 billion by 2026. This growth underscores the demand for superior mixing solutions.

When comparing leading agitator brands, certain features stand out. For instance, impeller design affects mixing efficiency significantly. A study showed that models with high-shear impellers can reduce blending time by 30%. Additionally, the material of construction can influence durability and performance, particularly in corrosive environments.

However, not all agitators perform as expected. Some face challenges related to energy consumption and wear over time. This raises important questions about the trade-offs between power and longevity. Engineers must continuously refine their selection criteria to balance these factors effectively. Understanding the strengths and weaknesses of each type is vital for optimal results in the long run.