In the realm of industrial mixing, the significance of a Tank Agitator Mixer cannot be overstated. As experts in the field understand, achieving optimal mixing efficiency directly impacts product quality and operational effectiveness. Dr. Emily Tran, a leading authority in mixing technology, emphasizes, “The right tank agitator mixer can dramatically influence the uniformity and consistency of your product, paving the way for improved processes and increased customer satisfaction.”

Tank Agitator Mixers are designed to enhance the chemical and physical interactions within a mixture, ensuring that components are evenly distributed and reactions occur uniformly. This efficiency not only leads to better end products but also minimizes waste and increases the overall productivity of manufacturing processes.

Understanding the dynamics of your mixing requirements is essential for selecting the appropriate Tank Agitator Mixer. The right choice can evolve your operations, ensuring that you meet the demands of an increasingly competitive market while maintaining high standards of quality and efficiency. As industries continue to innovate, embracing advanced mixing solutions becomes a critical step towards achieving operational excellence.

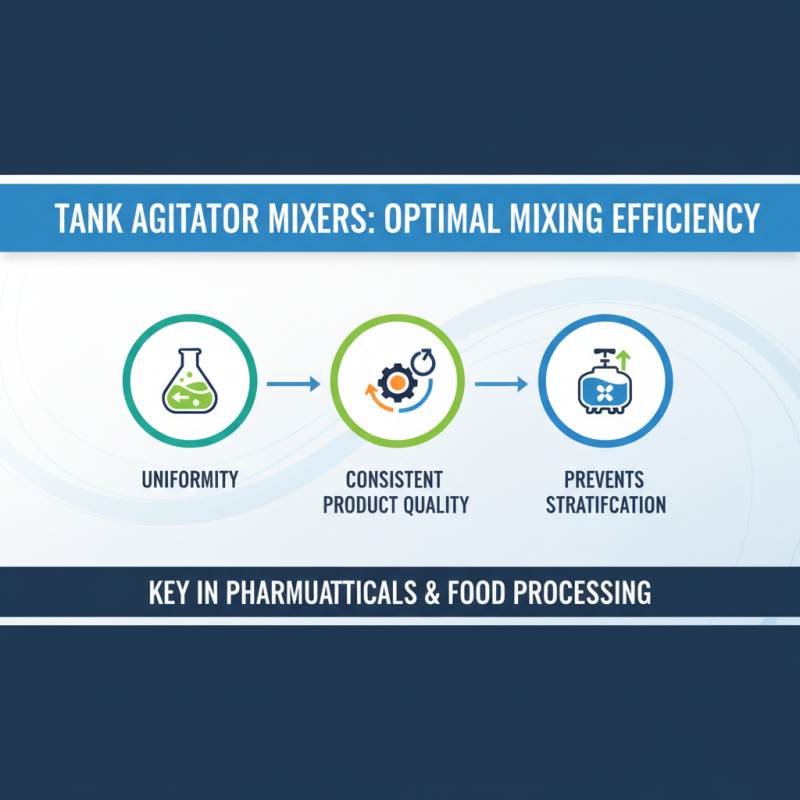

In various industrial processes, the importance of tank agitator mixers cannot be overstated. These mixers play a crucial role in ensuring that materials are uniformly blended, facilitating efficient chemical reactions and product consistency. Industries such as pharmaceuticals, food and beverage, and wastewater treatment rely heavily on these devices to maintain quality control and operational efficiency. Proper mixing facilitates the distribution of ingredients, enhances reaction rates, and ensures that products meet stringent regulatory standards.

Moreover, the design and operation of tank agitator mixers are tailored to meet the specific needs of different applications. For instance, in the food industry, mixers must not only ensure homogeneity but also prevent damage to delicate ingredients. In chemical manufacturing, the focus might be on achieving a particular viscosity or ensuring that solid particles remain suspended. The versatility of tank agitator mixers makes them an indispensable tool across sectors, enabling businesses to optimize their processes and achieve desired outcomes with maximum efficiency.

When it comes to achieving optimal mixing efficiency in various industrial processes, tank agitator mixers play a crucial role. One of the key benefits of using these mixers is their ability to create uniformity in mixtures, which is essential for consistent product quality. By ensuring that all components, whether liquid or solid, are thoroughly integrated, tank agitator mixers help prevent issues such as stratification or settling, which can occur in stagnant conditions. This uniformity is particularly important in industries like pharmaceuticals and food processing, where precise formulations are critical.

Another significant advantage of tank agitator mixers is their versatility. These mixers can be tailored to accommodate different viscosities and densities, allowing them to handle a wide range of materials efficiently. Whether mixing light fluids or thicker slurries, adjustable speed and design configurations enable operators to optimize the mixing process based on specific requirements. Furthermore, the use of advanced technologies in agitator designs often leads to reduced energy consumption, resulting in both cost savings and lower environmental impact—making them an effective choice for sustainable manufacturing practices.

In various industries, the importance of tank agitator mixers cannot be overstated. These mixers are essential for ensuring optimal mixing efficiency, particularly in sectors such as food and beverage, pharmaceuticals, and chemical processing. In food production, for instance, proper mixing is crucial for achieving the right consistency and flavor balance in products like sauces and dressings. The efficient mixing capabilities of these agitators guarantee that ingredients are uniformly blended, preventing settling and ensuring quality.

Tip: When choosing a tank agitator mixer, consider the viscosity of your materials. Specific designs are optimized for different viscosity levels, which can significantly affect the mixing process and the final product's quality.

In the pharmaceutical industry, tank agitator mixers serve a critical role in the formulation of medicines. These mixers help to maintain homogeneity in suspensions, ensuring that every dose delivers the intended therapeutic effect. Additionally, in chemical processing, proper agitation can facilitate reactions by promoting contact between reactants, ultimately improving yield and efficiency.

Tip: Regular maintenance of your agitator mixer is key to sustaining performance. Schedule routine inspections to identify wear or damage and replace components as necessary to maximize operational efficiency.

This bar chart illustrates the mixing efficiency of tank agitator mixers across various industry applications. The data points reflect how effectively mixers contribute to optimal mixing in different sectors, showcasing the importance of agitator mixers in ensuring high-quality products.

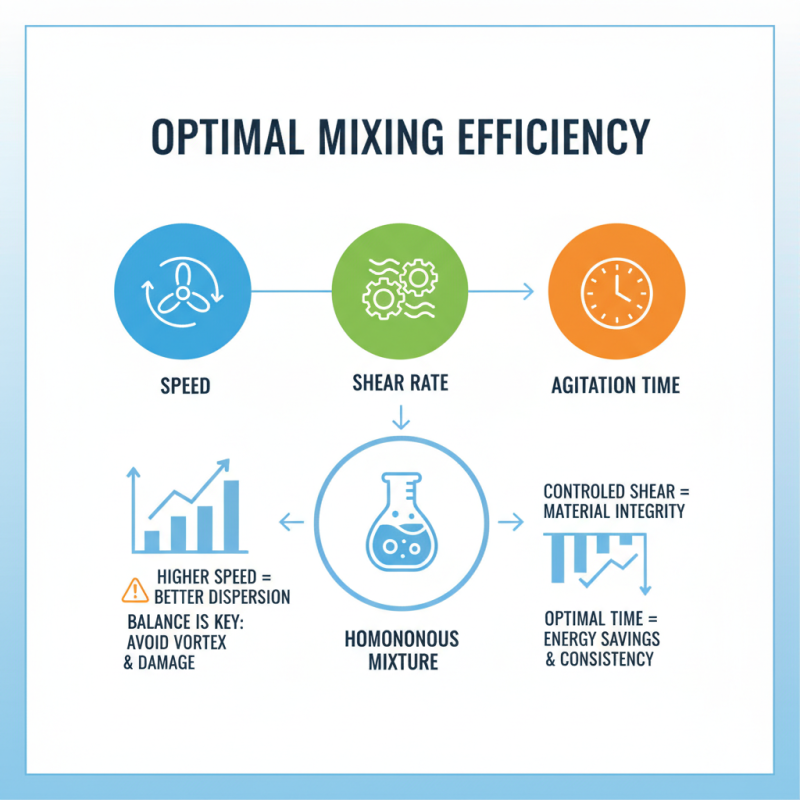

When it comes to achieving optimal mixing efficiency, three critical parameters must be carefully controlled: speed, shear rate, and agitation time. Each of these factors plays a pivotal role in determining how effectively materials can be blended together. The speed of the agitator mixer affects the overall energy input into the system; higher speeds typically result in more homogeneous mixtures, as they promote better dispersion of particles. However, finding the right balance is essential, as excessively high speeds can lead to undesirable conditions like vortex formation or shear damage to certain materials.

Shear rate is another vital consideration in the mixing process. It refers to the rate at which adjacent layers of fluid move with respect to each other and can significantly influence the texture and consistency of the final product. For instance, products requiring a fine particle size or specific viscosity may demand higher shear rates to ensure proper breakdown and uniformity. Furthermore, agitation time is also crucial. Sufficient mixing time allows for complete interaction between components, enhancing the final product's quality. Inadequate agitation time can leave certain ingredients unblended, leading to inconsistencies that could affect performance or degradation of quality. Therefore, ensuring optimal control over these parameters is essential for efficient and effective mixing operations.

When comparing tank agitator mixers to static mixers, it becomes evident that the former offers superior mixing efficiency that can significantly enhance various industrial processes. Tank agitator mixers use mechanical energy to create turbulence in the fluid, allowing for a more thorough and uniform mixing of components. This is particularly beneficial when working with materials of varying densities or viscosities, as the adjustable speed and design of agitators can be tailored to the specific needs of the mixture, ensuring a consistent end product.

On the other hand, static mixers rely on passive flow through designed channels to achieve mixing. While they can be effective in simple applications, their inability to adjust to changing material properties or flow rates limits their performance. In contrast, tank agitator mixers can dynamically respond to fluctuations in viscosity or solute concentration, which is essential in processes such as chemical reactions or food production, where precision is key. The comparative data clearly indicates that for operations requiring high levels of homogeneity and adaptability, tank agitator mixers outperform static mixers, making them a vital component for optimal mixing efficiency.

| Criteria | Tank Agitator Mixer | Static Mixer |

|---|---|---|

| Mixing Time (mins) | 2-5 | 5-10 |

| Energy Consumption (kWh) | 0.5-1 | 1-2 |

| Mixing Homogeneity (1-10 scale) | 9 | 6 |

| Setup Complexity (1-10 scale) | 4 | 7 |

| Maintenance Frequency (per year) | 2 | 1 |