The efficient management of waste is crucial for environmental sustainability. Industries generate vast amounts of sludge, which requires proper disposal. According to a 2022 report by the Global Waste Management Sector, an estimated 1.3 billion tons of waste is generated annually. This staggering figure underscores the need for effective waste treatment solutions.

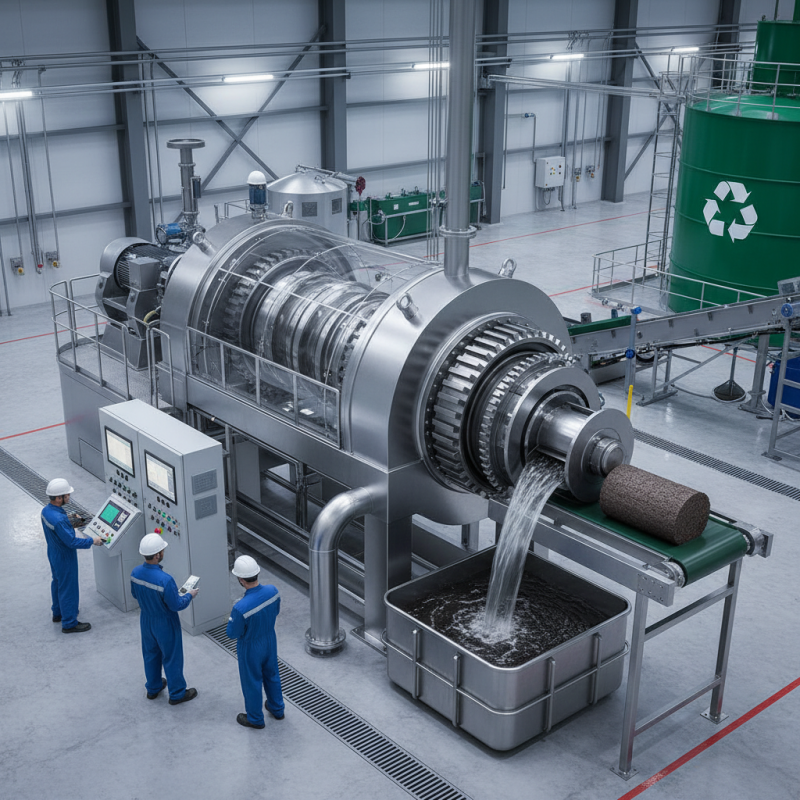

One innovative technology making strides in this field is the Screw Press Dewatering Machine. This machine significantly reduces waste volume and minimizes disposal costs. Industry studies suggest that it can achieve over 90% water removal from sludge. This capability not only enhances waste handling efficiency but also recycles water for reuse. However, initial investment and maintenance costs remain considerations for many facilities.

Effective waste management systems should be both cost-efficient and environmentally friendly. As more industries adopt the Screw Press Dewatering Machine, challenges are likely to emerge. It’s essential to continuously evaluate performance and address any operational shortcomings. Only then can the true potential of this technology be realized in achieving sustainable waste management practices.

Screw press dewatering machines play a significant role in waste management. These machines effectively reduce waste volume. They help in extracting water from sludge, making disposal easier. The process reduces landfill use and lowers transportation costs.

One key feature is the efficient separation of solids from liquids. This leads to a drier end product. The screw mechanism continuously pushes material through a sieve. This design ensures a consistent output. Many facilities benefit from this technology, but it requires regular maintenance to avoid clogs.

Tips for maximizing efficiency include monitoring moisture levels. Keeping a close watch helps adjust the system for optimal performance. Operators should ensure the feed material is evenly distributed. Uneven feeding can lead to wear and tear. Regular checks on the equipment can prevent costly downtime, a common oversight. Remember, improvement requires ongoing reflection and adjustments.

Screw press dewatering machines offer significant efficiency gains in waste management. They effectively reduce the volume of sludge, leading to lower disposal costs. Statistical data shows that using these machines can decrease water content in waste materials by up to 90%. This not only conserves resources but also optimizes space at disposal sites.

Tips for using a dewatering machine effectively: Regular maintenance is crucial. Ensure filters and screens are clean. This prevents clogs and maximizes output. Additionally, adjust the pressure settings to match the type of waste. Inconsistent pressure can lead to uneven dewatering results.

Another aspect to consider is operator training. Well-trained personnel can identify issues and optimize machine settings for different waste types. It's essential to reflect on the operational procedures periodically, assessing whether they align with the latest industry standards. Inefficiencies can often stem from outdated methods that don't consider new materials or waste characteristics.

This bar chart illustrates the efficiency gains from using screw press dewatering machines in waste management. The data shows the percentage reduction in moisture content of various types of waste before and after dewatering.

The screw press dewatering machine offers several cost-effective benefits in waste treatment. This technology efficiently separates liquids from solids, significantly reducing waste volume. According to a report by the Environmental Protection Agency (EPA), proper waste management can minimize landfill costs by up to 40%. This statistic highlights the financial incentives of adopting screw press technology.

Operating a screw press may initially seem expensive. However, maintenance costs can be lower than traditional systems. Some studies indicate that energy consumption in screw presses is 30% less than conventional methods. This translates into reduced operational costs over time. Furthermore, efficient dewatering can lead to increased revenue from the sale of dried materials. Many facilities report a 20% increase in income after implementing such systems.

There are challenges to consider. Not all waste types are suitable for screw presses. It’s crucial to analyze the specific waste characteristics. Some operators report lower efficiency with high-fat or sticky materials. Industry reports suggest a detailed feasibility study before implementation to enhance performance. Understanding waste composition can ultimately lead to better financial outcomes.

The screw press dewatering machine plays a crucial role in effective waste management. One of its significant benefits is the reduction of waste volume. According to a report by the Environmental Protection Agency, dewatering can reduce waste by up to 60%. This not only leads to lower disposal costs but also helps minimize landfill use. Landfills are a significant contributor to methane emissions, a potent greenhouse gas. By reducing waste volume, these machines help mitigate environmental impacts.

Pollution levels also drop significantly when employing screw press technology. Dewatered sludge is easier to manage and less hazardous. Studies indicate that managing waste properly can lead to a 50% decrease in harmful leachate production. This means cleaner local water sources and healthier ecosystems. Yet, the efficiency of these machines often depends on the type of waste processed. A lack of appropriate preprocessing can hinder results, highlighting the need for careful planning.

Tips: Always assess the type of waste before using a screw press. Adjust settings for optimal dewatering based on moisture content. Regular maintenance of the machine is essential to ensure longevity and efficiency. Remember, some operational tweaks may yield better environmental outcomes.

| Benefit | Description | Environmental Impact | Waste Volume Reduction (%) |

|---|---|---|---|

| Enhanced Water Recovery | Screw press machines efficiently separate water from waste materials, leading to higher liquid recovery. | Reduces water pollution and conserves water resources. | 50% |

| Reduction in Landfill Waste | By dewatering waste, the volume that needs to be sent to landfills is significantly reduced. | Lowers methane emissions from organic waste in landfills. | 70% |

| Cost Efficiency | Less waste disposal means reduced costs for waste management services. | Promotes sustainable waste management practices. | 60% |

| Improved Energy Efficiency | Screw presses consume less energy compared to traditional dewatering methods. | Less energy usage leads to a decrease in carbon footprint. | 30% |

| Versatile Applications | Effective for various waste types including sludge, food waste, and municipal waste. | Enables better waste segregation and processing. | 50% |

In recent years, many municipalities have embraced screw press dewatering machines for effective waste management. One notable case study involved a city struggling with organic waste. By implementing a screw press solution, they significantly reduced the volume of waste sent to landfills. The machine efficiently separated water from solids, resulting in compact, manageable waste. However, the city faced initial challenges in adjusting logistics to accommodate the new system.

Another success story comes from a food processing plant. They generated a large amount of sludge as a by-product. Using a screw press, they increased their dewatering efficiency by 50%. The dewatered sludge saved on disposal costs. Yet, the plant had to revisit their maintenance protocols. They learned that even a well-designed system requires regular upkeep.

In both cases, operators noted the importance of staff training. Understanding machine operation is crucial for maximizing efficiency. These stories highlight the potential benefits of screw press dewatering machines while also pointing out areas for improvement. Each implementation teaches valuable lessons that can shape future waste management strategies.