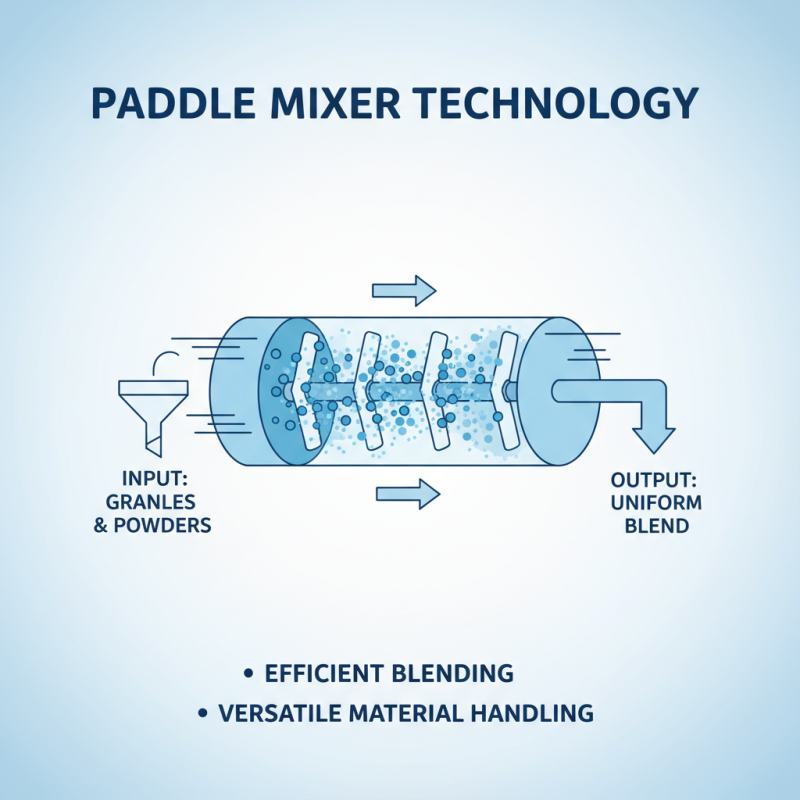

In the world of industrial mixing, the Paddle Mixer Machine stands out for its efficiency and versatility. John Smith, a leading expert in material handling, states, "A Paddle Mixer Machine is essential for achieving homogenous blends in various industries." This machine uses paddles to create a unique mixing motion, ensuring that materials are thoroughly blended.

With its ability to handle both dry and wet materials, the Paddle Mixer Machine has become a favorite in food production, pharmaceuticals, and construction. The design is straightforward but effective. However, improper use can lead to uneven mixtures. Users must pay attention to load limits and mixing times.

Operators may overlook maintenance schedules, which can affect performance. This reflects a common challenge in the industry. Finding the right balance between efficiency and care is crucial. Despite its effectiveness, the Paddle Mixer Machine requires thoughtful operation.

A paddle mixer machine is essential for many industrial processes. It blends various materials evenly, ensuring consistency. Often used in food production, pharmaceuticals, and construction, its design promotes efficient mixing.

The paddle design consists of a series of blades attached to a rotating shaft. These blades move materials in a circular motion. As the paddle spins, it lifts materials and mixes them together. The result is a uniform product. Users find it effective for powders, granules, and pastes.

However, using a paddle mixer can present challenges. Sometimes, it's hard to achieve the desired mix. The machine's speed must be adjusted for different materials. Users need to experiment with settings to improve efficiency. Regular maintenance is also crucial. Without it, performance may decline, leading to uneven mixes. Proper training is essential for optimal operation.

A paddle mixer machine is essential for blending dry and wet materials. Understanding its key components helps in optimizing its use. The paddle mixer consists of several vital parts.

The paddle blades are crucial. They ensure uniform mixing by creating a shearing action. The mixing chamber houses these blades. Its design affects mixing efficiency and product quality.

Another important element is the motor. It powers the mixer and can vary in speed. Selecting the right motor is critical. Too high a speed can lead to uneven mixing, while too low may not mix effectively. The drive system connects the motor and blades. It needs to be efficient to prevent energy wastage.

Tips: Regular maintenance is crucial. Check for wear and tear on the blades. Also, consider the materials being mixed. Some materials may stick to the paddle blades, causing issues. Cleaning them regularly can enhance performance. If the machine is not functioning as expected, inspect all components. Sometimes, a simple adjustment can lead to significant improvement.

Paddle mixers are essential in various industries for their efficiency in blending different materials. They operate using a series of paddles mounted on a rotating shaft. This design ensures that the materials mix uniformly. A typical paddle mixer can handle both granules and powders, making it versatile.

When materials enter the mixer, the paddles agitate them in a specific manner. The movement creates a flow that enhances mixing. According to industry reports, around 70% of the mixing efficiency depends on the speed and angle of the paddles. Finding the right balance is crucial. An incorrect setup can lead to uneven blending, causing quality issues in the final product.

During operation, factors like moisture content and material density also play significant roles. Too much moisture can clump materials together. Conversely, low moisture may lead to dust, creating workplace hazards. Regular maintenance and adjustments are necessary to ensure optimal performance. Some studies indicate that poorly maintained paddles can reduce mixing efficiency by up to 40%. Thus, operators need to monitor the machinery closely and reflect on performance metrics regularly.

Paddle mixers are versatile machines used in various industries. They combine materials effectively, which is essential in manufacturing processes. In the food industry, these mixers blend ingredients, ensuring uniformity in products. This can be seen in dough preparation for bread or pizza. The precise mixing ensures quality and consistency.

In the construction sector, paddle mixers are employed to mix concrete and mortar. This application is crucial. It guarantees that construction materials are homogenous, which impacts the durability of the structures. However, relying too much on these machines can lead to neglecting manual mixing techniques. Sometimes, hands-on approaches yield better results.

Chemical and pharmaceutical industries also utilize paddle mixers. Here, they mix different compounds, ensuring the right reactions occur. The balance between automation and manual input is delicate. Sometimes, machines miss nuances that a skilled worker would catch. This reliance on technology raises questions about how we maintain quality control in production processes.

Paddle mixer machines are essential in various industries. They offer substantial advantages in production efficiency and product quality. According to industry reports, these machines can achieve mixing homogeneity levels of up to 90%. This efficiency plays a crucial role in food processing, pharmaceuticals, and chemical manufacturing.

One significant benefit of paddle mixers is their ability to handle a wide range of materials. They can mix solids, liquids, and slurries effectively. The design allows for gentle yet thorough mixing, reducing the risk of material degradation. This versatility can improve overall production flow. However, not all material types yield the same results. Some blends may require further adjustments to achieve the desired consistency.

Another aspect to consider is the maintenance of paddle mixers. Regular upkeep is necessary to avoid unexpected downtime. Reports indicate that machines not properly maintained can lead to contamination issues. Such problems can affect product quality and increase waste. While paddle mixers can optimize production, they also come with their own challenges. Understanding these factors is crucial for maximizing their benefits in manufacturing.

Paddle mixer machines enhance production efficiency by reducing the mixing time for various ingredients. This bar chart illustrates the average mixing time for four different ingredients using a paddle mixer, highlighting the machine's effectiveness in managing workflow in production.