In the dynamic world of lab equipment, the Ibc Stirrer has become an essential tool for effective mixing. Dr. Emily Carter, a renowned expert in chemical engineering, emphasizes, "The right technique makes all the difference in efficient mixing." Understanding how to use an Ibc Stirrer effectively can elevate your mixing processes.

Effective usage isn't just about operating the device. It’s about knowing your materials and their properties. For instance, the viscosity of the liquid can significantly affect the stirring efficiency. Some users overlook this detail, resulting in suboptimal mixing. Think about it: a thick solution requires different stirring speeds compared to a thin one.

Moreover, positioning and timing matter when using an Ibc Stirrer. Ensure the stirrer is set at an optimal height and angle. Many technicians fail to adjust these settings, causing uneven mixing. Reflect on your current practices. If you’re struggling with consistent results, it may be time for a reevaluation. Implementing these practical tips can lead to noticeable improvements in your outcomes.

When it comes to IBC stirrers, understanding the types and functions is crucial. IBC stirrers are vital tools used in various industries, including food processing and chemical manufacturing. Two common types are the axial flow stirrer and the radial flow stirrer. Axial flow stirrers promote horizontal fluid movement, making them ideal for large volume mixing. In contrast, radial flow stirrers create vertical flow and are better suited for mixing smaller batches.

The performance of IBC stirrers can significantly affect production efficiency. According to a 2022 industry report, utilizing the right stirrer type can improve mixing time by up to 30%. However, many facilities still struggle with misapplication. Improper sizing or choice can lead to incomplete mixing. This often results in wasted resources and time, highlighting the importance of proper application and understanding.

Moreover, factors like viscosity and shear sensitivity play crucial roles in selecting the right stirrer. Inaccurate assessments can lead to product inconsistency. A study found that 25% of mixing problems stem from inadequate understanding of these factors. Making informed decisions about IBC stirrers is essential for achieving optimal performance in any mixing operation.

| Tip Number | Tip Title | Description | Type of IBC Stirrer |

|---|---|---|---|

| 1 | Choose the Right Size | Select a stirrer that fits the dimensions of your IBC container to ensure efficient mixing. | Portable Stirrer |

| 2 | Check Compatibility | Make sure the stirrer is compatible with the liquid being mixed. | Electric Stirrer |

| 3 | Adjust Stirring Speed | Optimize the stirring speed for the specific fluid viscosity. | Variable Speed Stirrer |

| 4 | Maintain Proper Position | Ensure the stirrer is positioned correctly to avoid dead zones in mixing. | Static Stirrer |

| 5 | Safety First | Always follow safety protocols when operating stirring equipment. | All Types |

| 6 | Clean After Use | Thoroughly clean the stirrer after each use to prevent contamination. | All Types |

| 7 | Monitor Mixing Duration | Keep track of how long mixing occurs for optimal results. | Variable Speed Stirrer |

| 8 | Use the Right Attachments | Select appropriate attachments based on the type of material being mixed. | Accessories Required |

| 9 | Inspect Equipment Regularly | Regular checks ensure that all equipment is functioning properly. | All Types |

| 10 | Train Operators | Ensure all users are trained in proper operation techniques. | All Types |

When using an IBC stirrer, there are key factors to keep in mind. Make sure to assess the viscosity of the material you are working with. Some materials may require a more powerful stirrer. Consider the size of your container as well. An incorrectly sized stirrer can lead to inefficient mixing.

Moreover, safety should never be overlooked. Always wear appropriate protective gear when operating the stirrer. Check that the stirrer is securely installed before starting. Vibrations can cause spills or accidents. It’s wise to review the stirrer's compatibility with the chemical composition of the liquids you plan to mix.

Inconsistent stirring can lead to uneven mixtures. Understanding how long to stir is crucial. Over-stirring can sometimes introduce unwanted air, impacting the final product. Alternatively, under-stirring may not achieve the desired results. Reflect on the mixing times needed for your specific application to ensure efficacy.

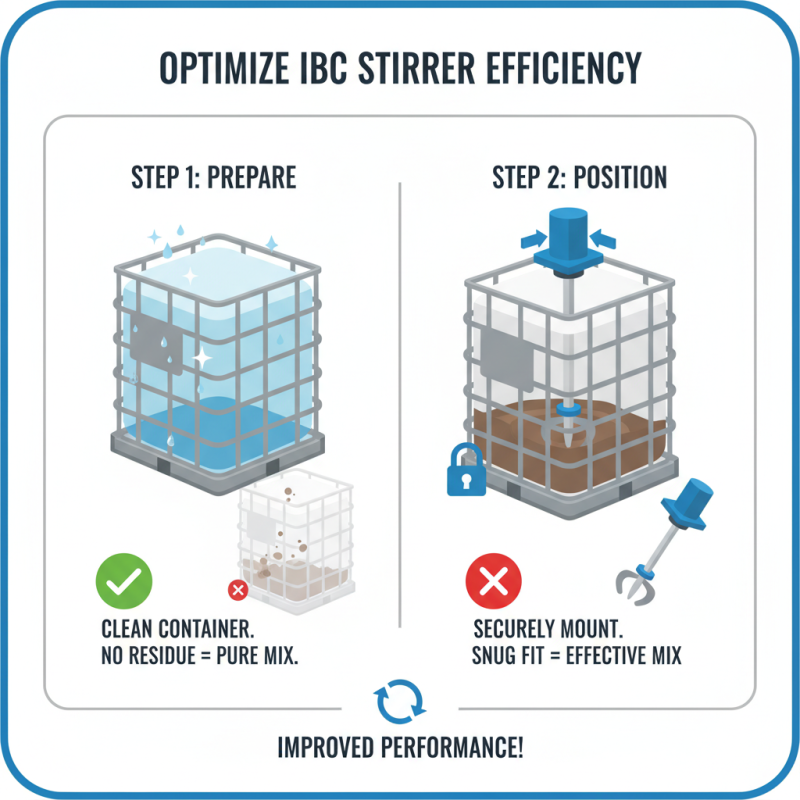

Setting up your IBC stirrer correctly can make a significant difference in efficiency. Begin by ensuring the IBC container is clean and free of residue. Any leftover materials can affect your mixing. A dirty container leads to poor results. Once the container is ready, position the stirrer securely. Make sure it fits snugly to prevent movement during operation. This is crucial for effective mixing.

Next, consider the speed settings of your stirrer. Start at a lower speed to gauge how your materials react. Gradually increase the speed if needed. Too high of a speed can cause splashing or uneven mixing. Monitor the consistency closely during this process. It's common to underestimate the time needed for thorough mixing. Keep an eye on progress, as rushing can result in incomplete blending. Always adjust your approach based on these observations.

Operating an IBC stirrer effectively is crucial for various industries, from food and beverage to chemicals. Understanding the right speed and duration can enhance mixing. A study found that improper stirring can result in a 30% decrease in product consistency. This loss significantly impacts product quality and ultimately customer satisfaction.

Regularly inspecting the stirrer for wear and tear is a best practice. Components like impellers can degrade over time. Replacing parts when necessary ensures efficiency. Additionally, inadequate cleaning of the equipment can lead to contamination. Data indicates that 45% of operational failures stem from improper maintenance.

Operator training is essential. Many users may overlook the proper techniques. Misalignment or incorrect setup can cause issues. A surprising 25% of operators admit to not following the manufacturer’s guidelines closely. Investing in training programs can significantly reduce these errors and improve overall performance. A more informed team leads to a smoother operation and better outcomes.

Proper maintenance of IBC stirrers is crucial for ensuring their longevity and efficiency. Regular checks of the stirrer's components can prevent unexpected breakdowns. For instance, it's recommended to inspect seals and gaskets every few months. Maintaining these parts can minimize leakage risks and enhance operational safety. According to a recent industry report, nearly 30% of stirrer failures stem from poor maintenance practices.

Cleaning IBC stirrers is also vital. Residue buildup can affect performance. Utilizing appropriate cleaning agents ensures that stirrers remain efficient. Some reports indicate that over 40% of performance issues arise from inadequate cleaning protocols. Operators should be trained to recognize when cleaning is necessary. A simple visual inspection can save time and costs down the line.

It's important to recognize the wear and tear that stirrers endure. Bearings and motors can degrade with heavy use. Regular lubrication can stave off friction-related issues. The frequency of lubrication should depend on usage intensity. Adapting to operational demands is key. Observing unusual sounds from the stirrer may indicate a need for immediate maintenance attention. Regular monitoring and quick reflection on performance can lead to prolonged life for IBC stirrers.