When it comes to enhancing the aeration process in deep-water environments, selecting the right equipment is crucial for optimal performance. The Deep-Water Self-Priming Submersible Jet Aerator stands out as an effective solution designed to improve oxygen levels in aquatic systems, making it essential for various applications such as wastewater treatment, aquaculture, and industrial processes. With numerous options available in the market, the ability to choose the best model can significantly impact operational efficiency and environmental sustainability.

In this guide, we will explore the key factors to consider when selecting a Deep-Water Self-Priming Submersible Jet Aerator. Understanding the intricacies involved in the design, capacity, and operational features of these aerators is vital for making an informed decision. This overview will not only highlight the essential specifications to look for but also provide insight into how to align the technology with specific operational requirements. By the end of this discussion, readers will be well-equipped to make a choice that enhances water quality and supports ecological balance in their deep-water systems.

Deep water self-priming submersible jet aerators play a crucial role in enhancing aquatic ecosystems by improving oxygen levels, facilitating the decomposition of organic matter, and promoting overall water quality. Unlike traditional aerators, self-priming jet aerators can operate in deeper water levels without the need for priming, making them highly efficient for larger bodies of water. These aerators utilize the Venturi effect, where high-velocity water is expelled through a nozzle, drawing in surrounding water to increase aeration. According to a recent industry report by the Water Environment Federation, the use of jet aerators can improve oxygen transfer efficiency by up to 30%, significantly benefiting applications in wastewater treatment plants and lakes.

When selecting the best deep water self-priming submersible jet aerator for specific needs, it's essential to evaluate factors such as wine depth, flow rate, and the volume of water being treated. Consideration should also be given to energy consumption and maintenance requirements, as these can impact overall operational costs. A study from the National Oceanic and Atmospheric Administration (NOAA) highlights that a well-chosen aerator can not only improve water quality but also reduce harmful algal blooms by enhancing the natural biodegradation processes.

Tips: Always ensure the aerator is appropriately sized for the targeted water area to prevent over- or under-aeration. Regular maintenance checks can also extend the lifespan of the equipment and ensure optimal performance. Be sure to review specifications related to power usage and aeration capacity to choose an aerator that aligns with your project's environmental goals.

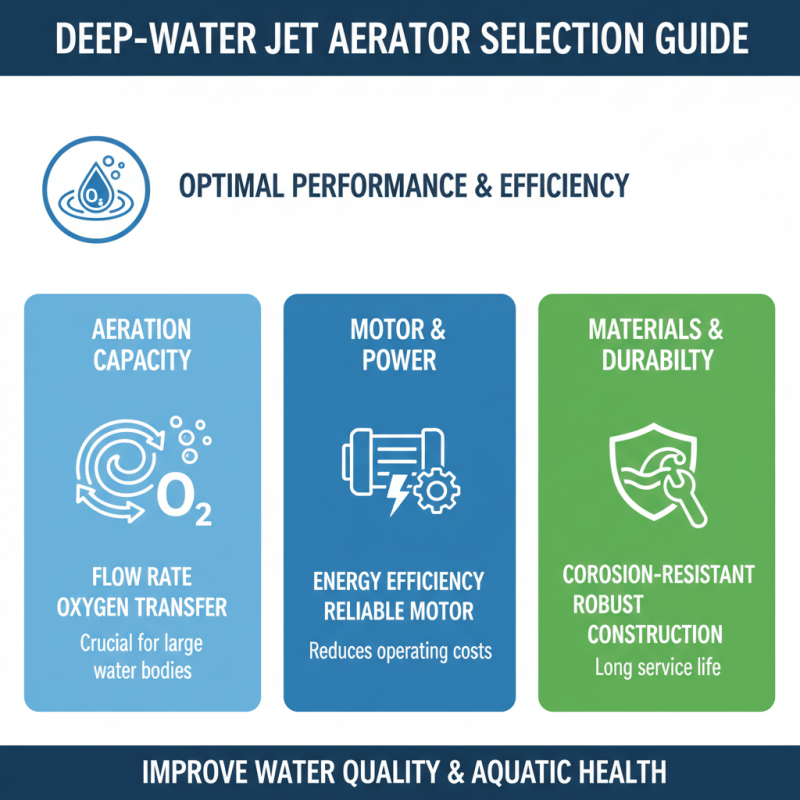

When selecting a deep water self-priming submersible jet aerator, it's crucial to consider several key features that ensure optimal performance and efficiency. First and foremost, pay attention to the aeration capacity of the unit. This is typically measured in terms of flow rate and the amount of oxygen it can effectively transfer to the water. A higher capacity is essential for larger bodies of water, as it directly impacts the health of aquatic life and the overall quality of the water.

Another important aspect to consider is the build quality and materials used in the aerator’s construction. Since these devices operate underwater, they must withstand harsh conditions, including pressure, corrosion, and potential debris. Look for jet aerators made from durable materials, such as stainless steel or high-quality plastics, which will ensure longevity and reduce maintenance needs. Additionally, evaluate the ease of installation and operation. A user-friendly design can make a significant difference, especially for those who may not have extensive technical expertise.

When selecting the best deep water self-priming submersible jet aerator, understanding the efficiency and energy consumption of these systems is crucial. Jet aerators are known for their ability to enhance oxygen transfer in deep water applications, and their energy efficiency directly impacts operational costs. According to a study by the Water Environment Federation, aeration typically accounts for 50-60% of the total energy consumption in wastewater treatment plants. Therefore, choosing an aerator with optimal energy consumption and high efficiency can lead to substantial savings over time.

Recent reports highlight that advanced jet aerators can achieve an oxygen transfer efficiency (OTE) of up to 2.0 kg O2/kWh under optimal conditions. This level of performance is significant, as it allows for a reduced number of aeration units needed, consequently decreasing both capital and operational expenses. Furthermore, energy-efficient designs often incorporate features such as variable speed drives and improved nozzle configurations, which enhance the aerator's performance while maintaining low energy consumption. By evaluating these parameters, operators can select jet aerators that not only meet their operational requirements but also contribute to a more sustainable future in water treatment processes.

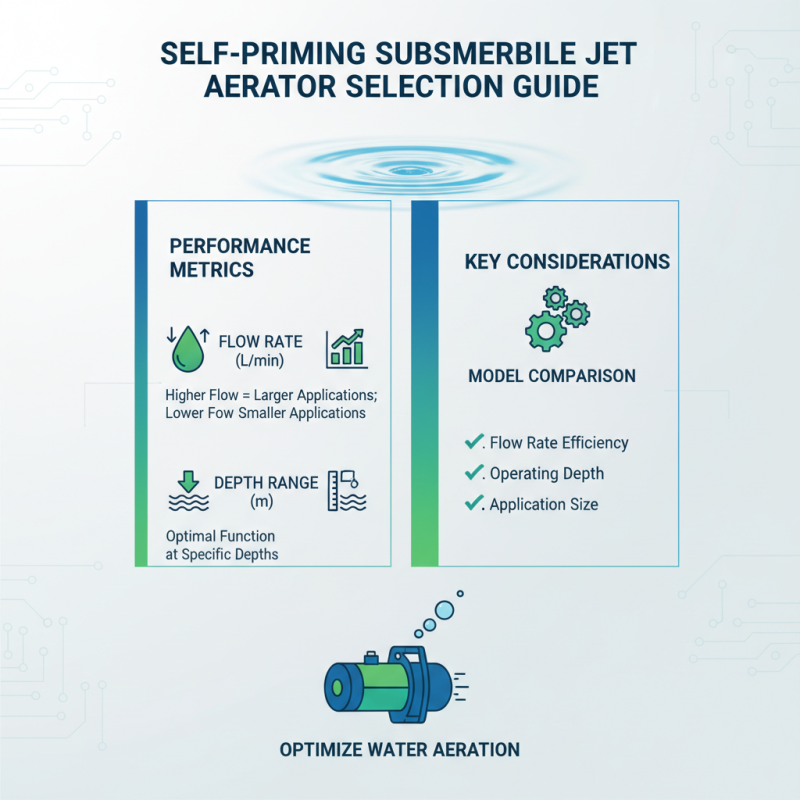

When selecting a self-priming submersible jet aerator, it's crucial to compare different models based on various performance metrics. One of the primary factors to consider is the flow rate, which indicates how efficiently the aerator can move water and introduce air. Models with higher flow rates are typically better suited for larger applications, while lower flow rates may be sufficient for smaller bodies of water. Additionally, examining the depth range of operation is essential, as certain models are designed to function optimally at specific depths, affecting their overall effectiveness in aerating the water.

Another significant aspect to evaluate is energy efficiency. Different models utilize various technologies that can impact power consumption rates. Selecting an aerator that combines high performance with low energy use can lead to significant cost savings over time. Furthermore, maintenance requirements vary among models; some may offer easy-access components for simplified care, while others may be more complex. Buyers should assess the ease of maintenance to ensure long-term operational reliability and minimal downtime. By comparing these characteristics, users can make an informed decision that aligns with their specific needs and environmental conditions.

When it comes to maintaining deep water self-priming submersible jet aerators, routine checks and preventive care are essential for optimal performance. One of the key maintenance tips is to regularly inspect the aerator for any signs of wear or damage. This includes checking components such as the impeller, casing, and seals. Any signs of corrosion or buildup can significantly impact the efficiency of the aerator, so addressing these issues promptly will prolong its lifespan and enhance its performance.

Another critical aspect of maintenance involves monitoring the aerator's operational parameters. Regularly evaluating energy consumption, flow rates, and pressure ensures that the unit is functioning within its designed specifications. If any parameters deviate from the norm, it may indicate a blockage or mechanical failure necessitating attention.

Clearing any debris in the intake area is vital to prevent clogging and maintain smooth operation. Implementing a consistent schedule for these checks, along with cleaning routines, will ensure that deep water jet aerators remain effective in optimizing water quality.