The increasing need for effective wastewater treatment solutions has brought the Multi Plate Screw Press into the spotlight. Experts emphasize its efficiency and operational advantages. Dr. Emily Carter, a leading authority in wastewater technology, states, "The Multi Plate Screw Press has revolutionized how we manage sludge." This innovative system minimizes waste volume while maximizing resource recovery.

Implementation of the Multi Plate Screw Press can lead to significant cost savings. Its design allows for high solids separation and low energy consumption. This results in a more sustainable wastewater treatment approach. However, users should consider the initial investment. While the technology offers advantages, careful planning is crucial to avoid potential setbacks.

Moreover, achieving optimal results requires operator training and system maintenance. Even the best technology can underperform without proper handling. The Multi Plate Screw Press presents a blend of efficiency and complexity. Its benefits are clear, but challenges in implementation cannot be overlooked.

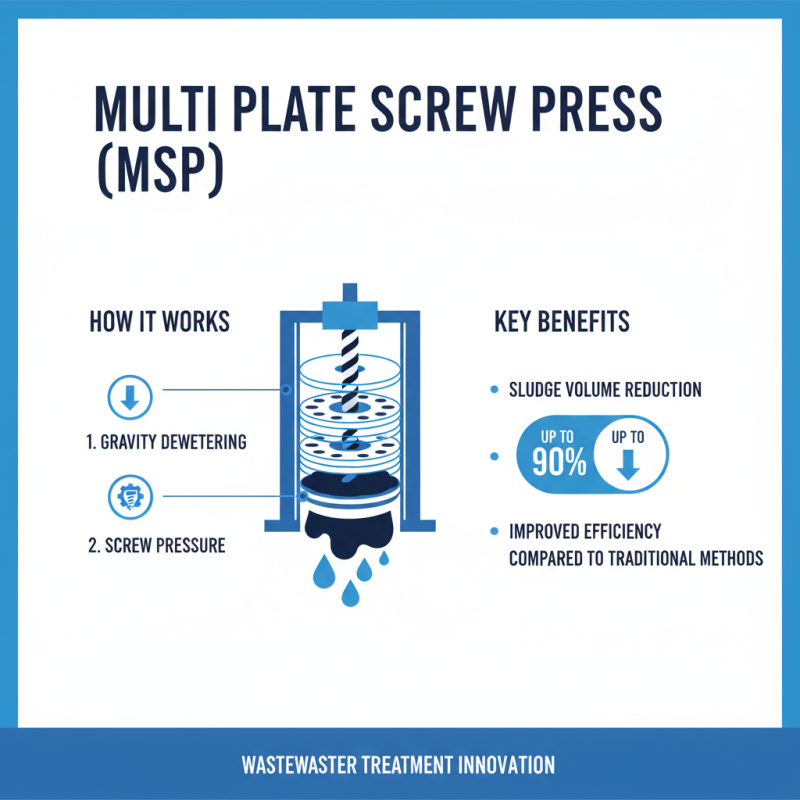

The Multi Plate Screw Press (MPSP) has become a game-changer in wastewater treatment. Its efficiency in dewatering sludge is remarkable. According to recent industry reports, MPSPs can achieve up to 90% solid content in dewatered sludge. This level of efficiency reduces disposal costs significantly.

MPSPs consume less energy compared to traditional dewatering methods. Studies show they can cut energy use by 30-50%. This energy saving not only lowers operational expenses but also reduces carbon footprints. Using less power is essential for sustainable practices in wastewater management.

Tip: Regular maintenance of the screw press ensures optimal performance. Routine checks can prevent unexpected breakdowns. Moreover, training staff on operational best practices can enhance efficiency. The right approach minimizes downtime.

Another concern is the initial investment. MPSPs may seem costly at first. However, the long-term savings on operational and disposal costs often make this choice viable. Reflect on the overall benefits rather than just the upfront expenses. Being an early adopter can position facilities as industry leaders.

The Multi Plate Screw Press (MPSP) has gained traction in wastewater treatment for its ability to significantly reduce sludge volume. This technology operates through a unique mechanism that combines gravity and screw pressure to dewater sludge effectively. According to a recent industry report, MPSP can achieve a reduction in sludge volume by up to 90%, a considerable improvement when compared to traditional methods.

Utilizing MPSP reduces the need for large storage tanks and decreases transportation costs. It can help facilities comply with stricter environmental regulations by minimizing waste. Some plants reported cutting their operational costs by nearly 30% after switching to MPSP systems. This transformative technology allows for more efficient resource management in wastewater treatment plants.

**Tip**: Regular maintenance of the MPSP is crucial for optimal performance. Ensure that any wear and tear is addressed promptly to avoid inefficiencies.

In addition, it is vital to consider sludge characteristics before implementation. Some sludge types may not yield the same reduction results. Facilities should perform pilot tests to refine their approach for best outcomes.

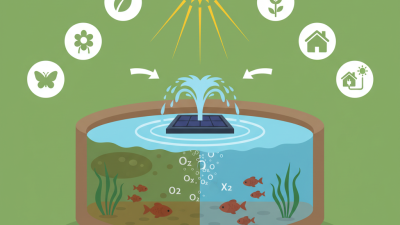

The use of Multi Plate Screw Press (MPSP) technology in wastewater treatment enhances resource recovery and water reusability. Research shows that MPSP systems can achieve up to 90% solid-liquid separation efficiency. This high efficiency leads to reduced sludge volume, which is crucial in minimizing disposal costs. By extracting valuable resources from wastewater, facilities can reclaim nutrients like nitrogen and phosphorus, promoting sustainable practices.

Tips for maximizing efficiency: Regular maintenance of the screw press is essential. A well-maintained device operates more effectively, ensuring optimal performance. Operators should monitor the feed consistency to avoid clogging issues. Unexpected downtime can lead to increased operational costs.

Water reusability is another significant advantage. According to recent industry studies, treated wastewater can be reused for irrigation, industrial cooling, and even potable applications. This not only conserves fresh water but also addresses the growing demand for water in various sectors. However, it’s important to ensure that the treatment processes meet regulatory standards before reuse. The trade-off between cost and efficiency remains a challenge worthy of reflection.

The multi-plate screw press is gaining traction in wastewater treatment. This technology offers significant cost advantages for facilities. It reduces energy consumption by efficiently separating solids from liquids. This efficiency translates into lower operational costs over time. Additionally, the system requires less maintenance compared to traditional methods.

Moreover, the initial investment in a multi-plate screw press is often offset by long-term savings. Facilities can save on labor and chemical requirements. The design minimizes waste generation, which also helps in reducing disposal costs. However, the upfront costs can be a concern for some operators. It’s essential to conduct a thorough cost-benefit analysis.

Another aspect is the adaptability of the system. It can handle various types of sludge with minimal modifications. But, every installation can come with unique challenges. Operators need to ensure proper training for staff. Without adequate knowledge, the promised efficiency may not be fully realized. Balancing these factors is key to maximizing the benefits of this technology.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| High Efficiency | Multi Plate Screw Press offers high solid concentration and fast dewatering. | Reduces energy consumption compared to traditional methods. |

| Low Maintenance | Requires less servicing and downtime, resulting in lower operational costs. | Minimizes repair costs and extends equipment lifespan. |

| Compact Design | Small footprint allows for easy installation in limited spaces. | Reduces infrastructure costs by minimizing additional space requirements. |

| Environmentally Friendly | Decreases sludge volume and enhances recovery of wastewater resources. | Lower environmental compliance costs and improved sustainability. |

| Versatility | Effective for various wastewater types, including food industry and municipal waste. | Flexibility in application leads to broader market potential and revenue opportunities. |

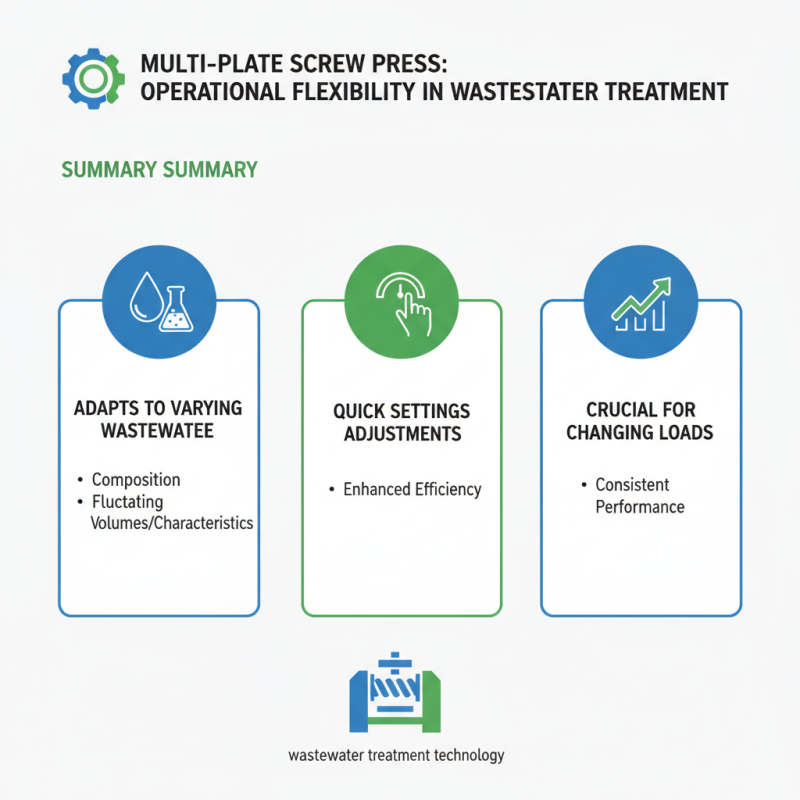

The operational flexibility of a multi-plate screw press in wastewater treatment plants is impressive. This technology adapts easily to varying wastewater compositions. Operators can adjust settings quickly, enhancing the efficiency of the process. This ability is crucial when dealing with fluctuating volumes and characteristics of waste.

Tips for using a multi-plate screw press effectively include running regular maintenance checks. This simple practice can prevent unexpected downtime. Also, consider training staff to recognize signs of wear or malfunction. A proactive approach will boost overall performance.

The screw press operates continuously, which means the flow can be constant. However, inconsistent input can lead to clogs. If that happens, processing times can stretch, reflecting poorly on the plant's efficiency. Maintaining uniform input helps avoid these issues.